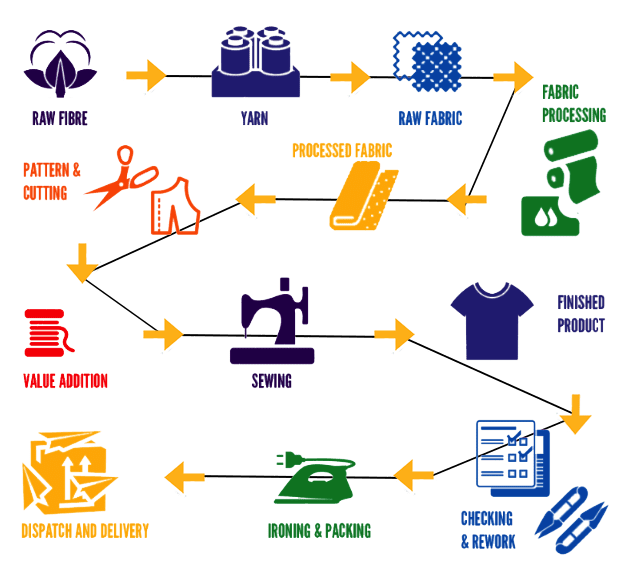

Manufacturing Process

Product Development

Extensive trend forecasting and market research is done a year in advance to predict popular styles, patterns, fabrics, colors, and silhouettes. Customer data analytics and feedback guides development.

Designers sketch creative concepts for dresses, tops, jumpsuits, matching sets, coordinating accessories etc. Technical flats illustrate back / front views, construction details, pockets, fastenings, trims.

The collections take shape with multiple deliveries planned across the season. Development timelines account for sourcing, production, and shipping.

Tech packs are made with all specs for each product style detailing dimensions, bill of materials, directional prints, embroideries etc.

Fabric Sourcing

For apparel, suitable fabrics like Jersey, Rib-knit, Interlock Knit, Mesh, French Terry, Fleece, Pique, viscose challis, rayon crepe, lightweight cotton voiles and linen blends are sourced in bulk. Minimums meet production yardages across size ranges.

Performance characteristics like drape, hand feel, stretch, transparency and breathability are assessed for each style. Sustainable fabrics may be prioritized.

Any custom designed prints are commissioned to overseas design studios and digitally printed. Placement repeats, color ways and scale sizes are specified.

Zippers, buttons, elastic, lace trims, embroidery threads, labels etc. are sourced simultaneously from authentic and recommended suppliers.

Rigorous testing ensures quality benchmarks for colorfastness, dimensional stability, durability etc are met for all materials.

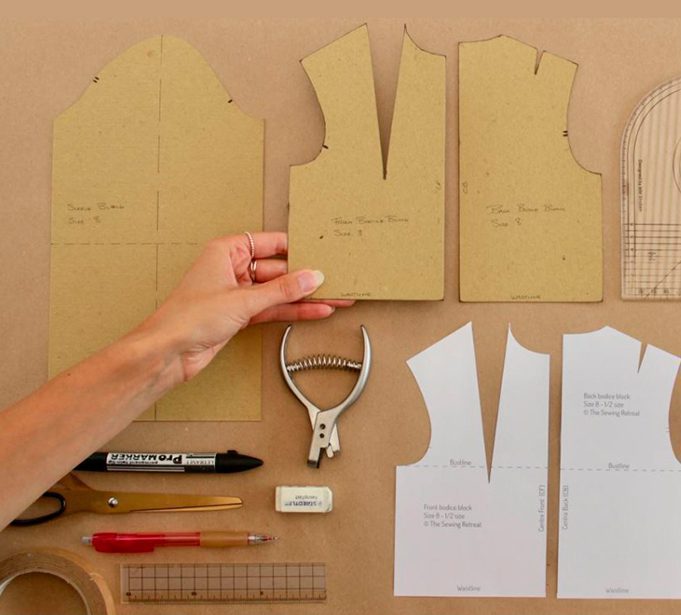

Patternmaking and Grading

Design sketches and specs sheets are used to draft paper master patterns for each style in the core sizes through manual grading rules or CAD software

Toiled muslin samples are tested for best construction, shape and fit. Adjustments made if necessary.

Final graded patterns digitized into marker making software to calculate layouts, yield percentages, cut order and fabric consumption.

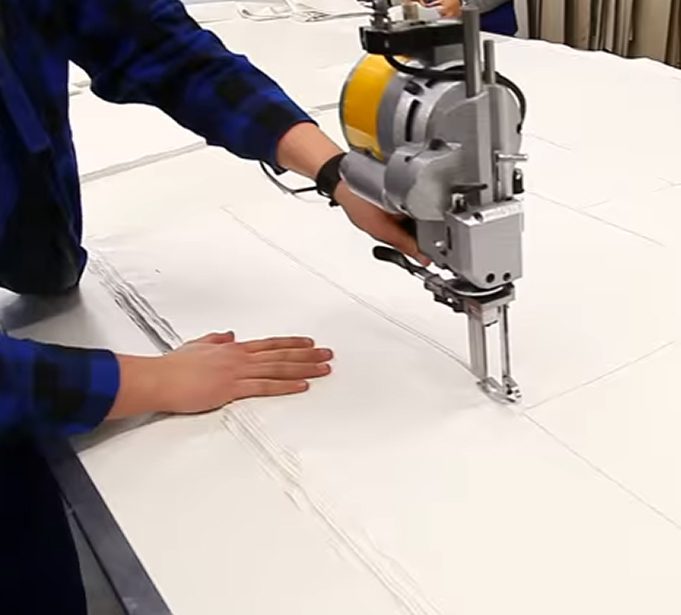

Fabric Cutting

Fabric Lots prepared through processes like inspection, relaxation etc. Multiple layers spread aligning pattern markers for high efficiencies. After lying Specified time given to lay for fabric relaxation.

Automated fabric cutting machines used to precisely cut garment components like sleeves, front, back and collars etc. After bundling special Labels are used to track bundling throughout production process.

Garment Assembly

Sections are transferred to dedicated sewing stations within parachute bags to maintain cleanliness during assembly operations. Competent sewers proficiently handle the machinery. Detailed steps like stitching darts, joining inseams/out seams, adding pockets, attaching trims happen sequentially per product specs through the assembly line.

Some operations may be outsourced to specialized factories, for e.g. intricate embroidery, digital printing, beading, laser-cutting etc.

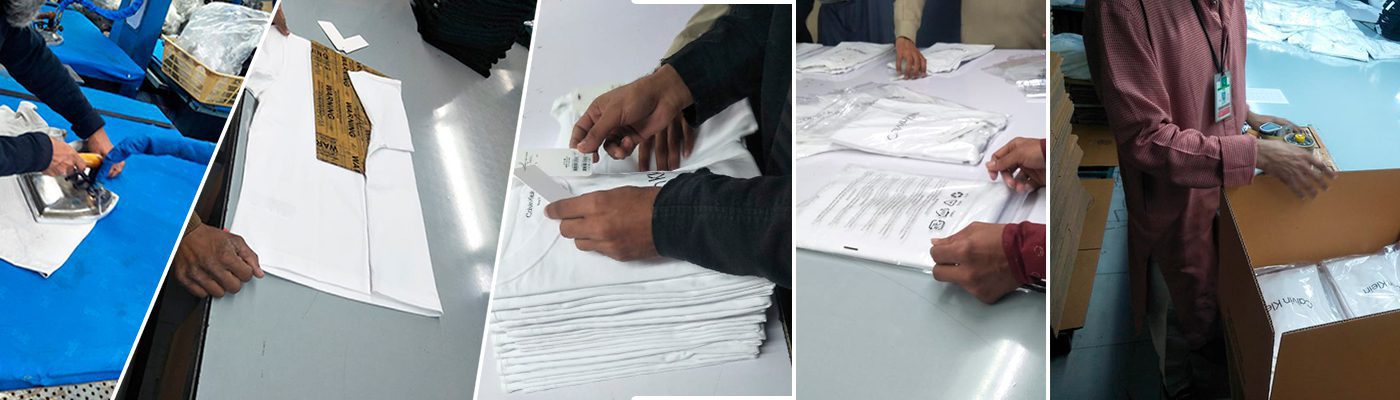

Finishing and Packaging

Post assembly, garments pass through thread trimming, pressing, spot cleaning etc. in finishing process. Meticulous final inspections ensure perfect quality before items packaged individually in poly bags or bulk case boxes for distribution.

After that packaging department attach Hangtags, price tags, folding, polybag and CTN making pro.

Quality Assurance

Gloed Industries Quality Assurance Depart is assuring the quality system and quality of product at each stage of manufacturing process through its team of professionals and affective procedures. We have well equipped team to perform the inspection as per customers given standards.